Silicon Provider Ionobell Drops In

Ionobell CEO touts bringing silicon battery technology to scale using pre-existing manufacturing processes and technology.

April 1, 2024

Battery makers, EV manufacturers, consumer electronics giants, and many more are actively assessing and pursuing the promise of increased energy density, reduced weight, and higher performance with silicon and silicon anodes in battery design.

A significant headwind, though, given current consumer uncertainty for EVs and pauses in battery plant construction, is the billions of dollars and years of work bringing new battery manufacturing plants online and to scale.

But what if battery makers could make the move to superior silicon-based technology using their existing equipment and processes?

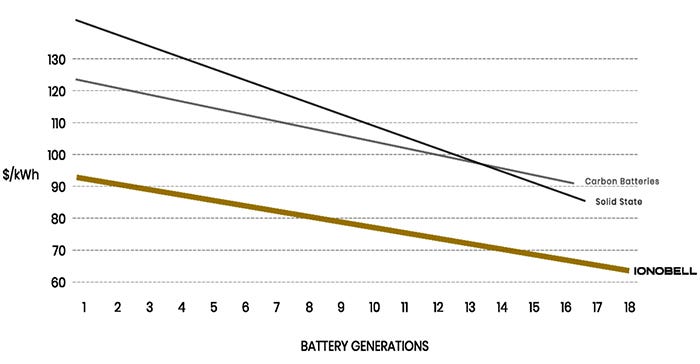

San Jose, CA-based silicon provider Ionobell is setting out to show that it can happen. Ionobell provides porous nano-particle silicon in collaboration with customers to provide silicon-dominant batteries in existing processes on existing equipment—no new facilities necessary.

“Through collaboration, we can customize our particles to match customer priorities and processes,” Ionobell founder and CEO Rob Neivert recently told Battery Technology. Markets are only growing more competitive, so providing superior technology and being first to market is so important that the time and cost to build new facilities is a huge disadvantage, he noted. “By ‘dropping in’ new materials and production approaches on existing plant setups and equipment, new batteries and their advantages are delivered much quicker at drastically reduced costs.”

Ionobell CEO Rob Neivert. Credit: Ionobell

How to do it

With a headcount of not 500 or 50 but only five, Ionobell needs to bring formidable expertise to the table. Company co-founder and CTO Robert Ionescu is a former battery research scientist at HP and is a recognized nanomaterials and energy storage expert. Whether it involves supplying customized silicon nanoparticles or dropping in production processes for silicon anodes or complete battery production on existing equipment, the result is cheaper, more accessible silicon battery output (including solid state and other battery formulations for different uses) that customers can license across all stages of production.

“Start knowing you’re going to do this,” Neivert advises: Saving significant time and money are not the only goals; collaborating across the entire supply chain opens up even more advantages, like incorporating the waste stream and battery recycling into the production process.

Attracting investment

On March 26, Ionobell announced that they raised a recent seed extension round of $3.9M led by Dynamo Ventures and Trucks VC bringing the total amount funding to $7.3M in seed investment fundraising. The initial equity round was led by Trucks VC, with participation from Dynamo Ventures and Alumni Ventures.

“Almost every single product we use in our daily lives, from our phones to our cars to our coffee machines, uses batteries,” Neivert stated in the announcement. “What the average consumer doesn’t realize, however, is that these batteries are produced through a multitude of different technology providers and partnerships. At Ionobell, we want to give manufacturers and producers better solutions for their demanding battery customers.” That means creating silicon-forward batteries that are more energy-efficient, cost-effective, and are a drop-in solution with their existing processes/equipment—both solid-state and standard lithium-ion, he stated.

Enabling lower costs across more battery generations. Chart source: Ionobell

Expanding production

With its new funding, Ionobell plans on expanding its production across the United States, bringing recycled battery material to new manufacturers and a broader array of industries.

“At Dynamo, we believe in investing in the future of supply chain and mobility,” says Jon Bradford, Managing Partner of Dynamo Ventures. “Ionobell’s novel battery technology from reused materials can power the technology in our everyday lives. The impact will not be just felt in the end products that we use but also in manufacturing, transportation, and supply chain, effectively from conception to creation to distribution. In the quest to create a better, greener global industry, Ionobell is leading the charge by quite literally powering the future.”

“Come collaborate,” Neivert concludes. “Collaboration generates superior results.”

About the Author(s)

You May Also Like