Nissan’s Solid-State Plans Revealed: SSB-Powered EVs by 2029

Automotive giant Nissan unveiled its plans for solid-state battery-powered EV production at the site of its under-construction pilot line.

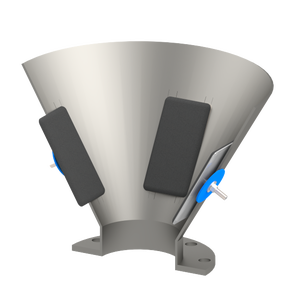

Nissan's pilot production line is being set up at the company's Yokohama facility.Image courtesy of Nissan

On April 16, Nissan showed its in-construction all-solid-state battery (SSB) pilot line to members of the media at its Yokohama Plant in Kanagawa Prefecture. At the event, the automotive giant unveiled plans to revolutionize battery technology with the mass production of solid-state batteries (SSBs) by early 2029. Nissan plans to begin operating the pilot production line by March 2025, with commercial production of EVs set to start in fiscal year 2028–2029.

The promise of SSBs

The global automotive industry is undergoing a transformative shift towards electrification, with electric vehicles (EVs) becoming increasingly prominent on roads worldwide. Central to this transition are advancements in battery technology, particularly the development of solid-state batteries. These next-generation batteries, which replace corrosive liquids with solid metals, offer promises of increased energy density, faster charging times, enhanced safety, and improved longevity compared to traditional lithium-ion cells.

Nissan's journey towards solid-state battery production is marked by innovative manufacturing strategies aimed at maximizing efficiency and scalability. Reuters reports that the automaker plans to deploy cutting-edge casting machines at its unfinished pilot plant in Yokohama to drive down costs.

Nissan has used casting boards for structural parts of front air conditioners for over 15 years at its Tochigi plant, said Hideyuki Sakamoto, executive vice president for manufacturing and supply chain management, according to Reuters: “In the end, we decided to use a 6,000 tonnes gigacasting machine to make the rear body structure of cars using aluminium casting.”

By leveraging advanced technologies at its Yokohama pilot plant, Nissan aims to accelerate the transition to solid-state batteries, with plans to ramp up production to 100 megawatt hours per year by the late 2020s.

The race to production

As automakers vie for supremacy in the EV market, the race to commercialize solid-state batteries has intensified, with Asian firms leading the charge.

While Nissan is making strides in solid-state battery technology, it faces stiff competition from other automakers, particularly other Asian firms. In January an alliance of China-based battery makers, EV makers, research facilities and government institutions, dubbed China All-Solid-State Battery Collaborative Innovation Platform (CASIP), was formed with the aim of creating a supply chain for solid-state batteries by 2030.

Other companies are even more aggressive: China-based EV maker GAC and Japan’s Toyota are aiming to launch EVs powered by solid-state batteries as early as 2026 and 2027, respectively.

As Nissan CEO Makoto Uchida stated in March, emerging players are making inroads at incredible speed, necessitating a departure from conventional wisdom and a traditional approach.

In response to the competitive landscape, Nissan has entered into strategic partnerships to bolster its position in the EV market. The recent agreement between Nissan and Honda to collaborate on EV research and development underscores the industry's recognition of the need for innovative approaches.

At the press event, Nissan VP Shunichi Inamijima remarked on the significance of Nissan's solid-state battery technology, stating, "We are finally in the phase of scaling up on our all-solid-state battery line, AP reported him saying: "Our all-solid-state battery technology is a game-changer for making EV sales grow explosively."

A look at the production lines

The pilot production line comes almost exactly two years after Nissan opened the doors to its SSB prototype production line in April 2022. Click through to see photographs of both lines.

About the Author(s)

You May Also Like